Precision mechanical machining

Turning

We specialise in the manufacture of small parts, even for single parts and small batches. Our manual and numerical control lathes can carry out works up to a maximum diameter of 800 mm.

Thanks to the purchase of a Samsung CNC Lathe with relevant 3 metre bar feeder, we can now provide a higher number of products (up to Ø65), always of high quality, with processing times and serial production.

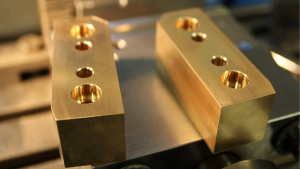

Milling

Our machinery park is composed of manual, traditional mills, and numerical control workbenches.

We can machine parts in various measurements through contract work or full supply, starting with small dimensions up to a maximum measurement of approx. 2,000×800×750 mm.

Grinding

Our machinery park also includes an ALPA tangential grinding machine which allows us to carry out grinding works both on soft materials and harder ones.

Workable materials:

We can machine various materials:

- Stainless steel

- Free-cutting steel

- Iron

- Reclaimed material

- Aluminium

- Superalloys

- Brass

- Bronze

- Copper

- Plastic materials (PP/PE/PVC/DELRIN/NYLON/TEFLON)

External treatments

We have been collaborating for years with companies active in the surface heat treatments and special machining sector, thereby allowing us to guarantee a highly qualified end product.

The treatments which can be carried out are:

- Tempering

- Nitriding

- Galvanising

- Chrome-plating

- Anodizing

- Sanding

- Burnishing

- Painting

CAD/CAM drawings and programming

Our internal technical office deals with creating mechanical drawings in 2D and 3D both for all our internal machining and for project and drawing development at the client’s specific request. The machining on our CNC workbenches is carried out with CAD/CAM programming.

The software used by us: Autodesk Autocad, Inventor, Solidwork, Esprit.